жсЯђСуВДЫЩБШНсЙЙаФбЊЙмжЇМмЕФЩшМЦЁЂ3DДђгЁгыБэеї(2)

4.3.1. Ш§ЕуЭфЧњВтЪд

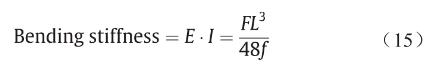

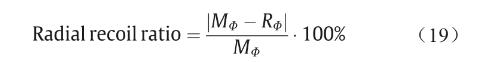

Ш§ЕуЭфЧњЪдбщгУРДМьВтжЇМмЕФЭфЧњадФмЃЈШсЫГадЃЉЃЌШсЫГадКУЕФжЇМмдкжЇМмНщШыжЮСЦЙ§ГЬжаФмЙЛИќШнвзЭЈЙ§ЖЏТіЭфЧњВПЗжЁЃжЇМмШсЫГадДѓаЁгУЭфЧњИеЖШРДБэЪОЃКЭфЧњИеЖШдНДѓЃЌжЇМмШсЫГаддНаЁЁЃЭфЧњИеЖШЭЈЙ§EЁЄ I МЦЫуЃЌОпЬхБэЪОЮЊ[26,28]ЃК

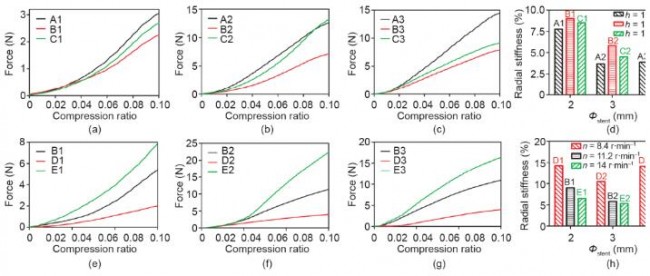

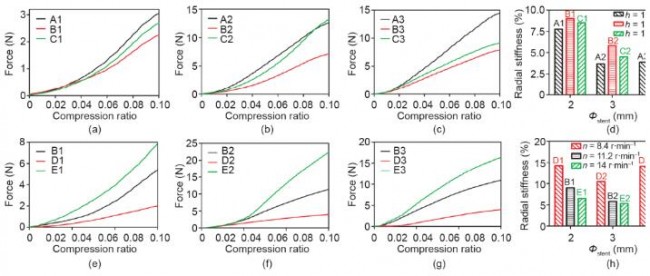

ЪНжаЃЌFЮЊЭтЭфЧњСІЃЛLЮЊжЇМмПчЖШЃЛfЮЊжЇМмЭфЧњФгЖШЁЃБОЪЕбщжаЃЌLЮЊ11 mmЃЌвђДЫЃЌЕББфаЮfЩшЮЊЙЬЖЈжЕЃЌЖдгІИќаЁЭтСІFЕФжЇМмОпгаИќКУЕФжЇМмШсЫГадЁЃЕББфаЮf ЮЊ2 mmЪБЃЌAЁЂBЁЂCШ§зщжЇМмЖдгІЕФЭтСІFШчЭМ9ЃЈdЃЉЫљЪОЃЛBЁЂDЁЂEШ§зщжЇМмЖдгІЕФЭтСІFШчЭМ9ЃЈhЃЉЫљЪОЁЃ

гЩЭМ9ЃЈaЃЉ~ЃЈdЃЉПЩжЊЃЌAЁЂBЁЂCШ§зщШсЫГадЙиЯЕЮЊB1 < A1 Ёж C1ЁЂA2 < B2 < C2КЭA3<B3<C3ЃЛЫцзХСЌНгИЫГЄЖШДг1.00 mmдіМгЕН1.50 mmЃЌЖдЇЖ2ЁЂЇЖ3КЭЇЖ4жЇМмЃЌИїзщМфЕФCзщгыAзщжЇМмЃЈC1/A1, C2/A2, C3/A3ЃЉЭтСІFжЎБШЗжБ№ЮЊ1.01ЁЂ0.77ЁЂ0.49ЁЃгЩЭМ9ЃЈeЃЉ~ЃЈhЃЉПЩжЊЃЌBЁЂDЁЂEШ§зщШсЫГадЙиЯЕЮЊE1 < B1 < D1ЁЂE2 < B2 < D2ЁЂE3 < B3 < D3ЁЃ

ЭМ9.ВЛЭЌНсЙЙКЭжЦдьВЮЪ§ЕФ3DДђгЁPCLжЇМмЕФШ§ЕуЭфЧњВтЪдНсЙћЁЃЃЈaЃЉ~ЃЈcЃЉжЇМмСЌНгИЫГЄЖШЗжБ№ЮЊ1 mmЁЂ1.25 mmКЭ1.5 mmЪБЃЈЖдгІAЁЂBЁЂCШ§зщЃЉЃЌИїзщжЇМмЭтСІFгыжЇМмБфаЮЧњЯпЭМЃЛЃЈdЃЉЕБжЇМмБфаЮЮЊ2 mmЪБЃЌИїзщжЇМмЖдгІЕФЭтСІFДѓаЁЃЛЃЈeЃЉ~ЃЈgЃЉТнИЫХчЭЗзЊЫйЮЊ8.4 rЁЄmin−1 ЁЂ11.2 rЁЄmin−1 КЭ14 rЁЄmin−1 ЃЈЖдгІDЁЂBЁЂEШ§зщЃЉЪБЃЌИїзщжЇМмЭтСІFгыжЇМмБфаЮЧњЯпЭМЃЛЃЈhЃЉЕБжЇМмБфаЮЮЊ2 mmЪБЃЌИїзщжЇМмЖдгІЕФЭтСІFДѓаЁЁЃЭМЃЈdЃЉКЭЃЈhЃЉжаЕФЪ§ОнвдЦНОљжЕЁРЮѓВюЗНЪНБэЪОЁЃ

ЭМ9.ВЛЭЌНсЙЙКЭжЦдьВЮЪ§ЕФ3DДђгЁPCLжЇМмЕФШ§ЕуЭфЧњВтЪдНсЙћЁЃЃЈaЃЉ~ЃЈcЃЉжЇМмСЌНгИЫГЄЖШЗжБ№ЮЊ1 mmЁЂ1.25 mmКЭ1.5 mmЪБЃЈЖдгІAЁЂBЁЂCШ§зщЃЉЃЌИїзщжЇМмЭтСІFгыжЇМмБфаЮЧњЯпЭМЃЛЃЈdЃЉЕБжЇМмБфаЮЮЊ2 mmЪБЃЌИїзщжЇМмЖдгІЕФЭтСІFДѓаЁЃЛЃЈeЃЉ~ЃЈgЃЉТнИЫХчЭЗзЊЫйЮЊ8.4 rЁЄmin−1 ЁЂ11.2 rЁЄmin−1 КЭ14 rЁЄmin−1 ЃЈЖдгІDЁЂBЁЂEШ§зщЃЉЪБЃЌИїзщжЇМмЭтСІFгыжЇМмБфаЮЧњЯпЭМЃЛЃЈhЃЉЕБжЇМмБфаЮЮЊ2 mmЪБЃЌИїзщжЇМмЖдгІЕФЭтСІFДѓаЁЁЃЭМЃЈdЃЉКЭЃЈhЃЉжаЕФЪ§ОнвдЦНОљжЕЁРЮѓВюЗНЪНБэЪОЁЃ

© Engineering

Бэ3ЫљЪОЮЊБфаЮfЮЊ2 mmЪБЃЌИїзщжЇМмЕФЭфЧњИеЖШжЕЃЈЦНОљжЕЃЉЁЃОнБЈЕР[29]ЃЌДЫЧАЩЬвЕЛЏЕФAbsorb GT1 жЇМмЭфЧњИеЖШжЕЮЊ4.20 NЁЄ mm2 ЃЌетгыA1ЁЂC1ЁЂC3ЁЂ D1~D3ЕШМИзщжЇМмЭфЧњИеЖШжЕНгНќЁЃвђДЫЃЌA1ЁЂC1ЁЂ C3ЁЂD1~D3жЇМмОпгаЯрЖдКЯЪЪЕФЭфЧњШсЫГадЁЃ

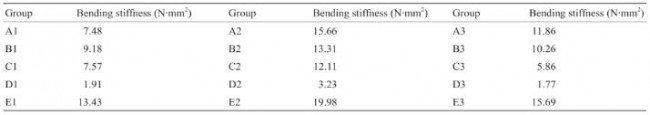

Бэ3 3DДђгЁPCLжЇМмЪЕбщИїзщЭфЧњИеЖШжЕ

4.3.2. ОЖЯђбЙЫѕВтЪд

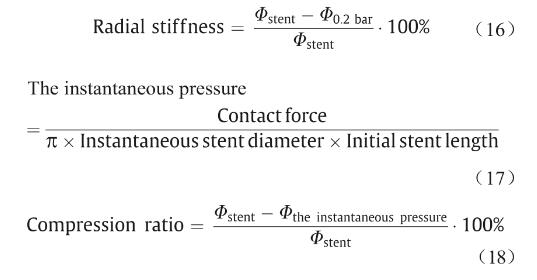

ОЖЯђбЙЫѕЪдбщгУгкЦРЙРОЖЯђЧПЖШЃЌДгЖјШЗЖЈжЇМмЕФОЖЯђжЇГХСІЁЃОпгаСМКУОЖЯђЧПЖШЕФжЇМмПЩвдЬсЙЉИќКУЕФжЇГХЁЃОЖЯђЧПЖШПЩвдгУОЖЯђИеЖШБэЪОЃКОЖЯђИеЖШдНДѓЃЌОЖЯђЧПЖШдНаЁЁЃSchmidtЕШ[30]ЬсГіНЋжЇМмОЖЯђИеЖШЖЈвхЮЊжЇМмжБОЖДгЭтбЙ0ЕНЭтбЙ0.2 bar (1 bar = 105 Pa)ЪБЕФБфЛЏГЬЖШ[ЪНЃЈ16ЃЉ]ЁЃASTMБъзМF3067-14 [27]НЈвщЪЙгУЫВЪБжЇМмжБОЖРДМЦЫужЇМмбЙЫѕБШЃЌЖјЗЧНіЪЪгУГѕЪМжБОЖ[ЪНЃЈ17ЃЉЁЂЃЈ18ЃЉ]ЁЃвђДЫЃЌОЖЯђИеЖШЪЧЕБзїгУдкжЇМмЩЯЕФЫВЪБбЙСІЮЊ0.2 barЪБЕФбЙЫѕБШЁЃ

жЇМмОЖЯђЧПЖШжївЊгыжЇГХИЫПэЖШtвдМАZаЮЛЗЪ§ФПгаЙиЁЃгЩЭМ10ЃЈaЃЉ~ЃЈdЃЉПЩжЊЃЌAЁЂBЁЂCШ§зщжЇМмОЖЯђИеЖШЙиЯЕЮЊBi>Ci>AiЃЈi = 1, 2, 3ЃЉЃЌвђДЫШ§зщжЇМмОЖЯђЧПЖШЙиЯЕЮЊBiЃМCiЃМAiЃЈi = 1, 2, 3ЃЉЃЛгЩЭМ10ЃЈeЃЉ~ЃЈhЃЉПЩжЊЃЌBЁЂDЁЂEШ§зщжЇМмОЖЯђИеЖШЙиЯЕЮЊDi>Bi>EiЃЈi = 1, 2, 3ЃЉЃЌвђДЫШ§зщжЇМмОЖЯђЧПЖШЙиЯЕЮЊDiЃМBiЃМEi (i = 1, 2, 3)ЁЃ

ОнБЈЕР[30]ЃЌЩЬвЕЛЏжЇМмОЖЯђИеЖШДг0.51%ЕН 3.99%ЃЌетгыA2ЁЂA3ЁЂC2ЁЂC3ЁЂE3жЇМмЯрНќЁЃвђДЫЃЌ A2ЁЂA3ЁЂC2ЁЂC3ЁЂE3жЇМмОпгаЯрЖдКЯЪЪЕФОЖЯђЧПЖШЁЃ

ЭМ10.ВЛЭЌНсЙЙКЭжЦдьВЮЪ§ЕФ3DДђгЁPCLжЇМмЕФОЖЯђЭфЧњВтЪдНсЙћЁЃЃЈaЃЉ~ЃЈcЃЉжЇМмСЌНгИЫГЄЖШЗжБ№ЮЊ1 mmЁЂ1.25 mmКЭ1.5 mmЃЈЖдгІAЁЂBЁЂCШ§зщЃЉЪБЃЌИїзщжЇМмЭтСІFгыжЇМмбЙЫѕБШЧњЯпЭМЃЛЃЈdЃЉЃЈaЃЉ~ЃЈcЃЉжаИїзщжЇМмОЖЯђИеЖШДѓаЁЃЛЃЈeЃЉ~ЃЈgЃЉТнИЫХчЭЗзЊЫйЮЊ8.4 rЁЄmin−1 ЁЂ11.2 rЁЄmin−1 КЭ14 rЁЄmin−1 ЃЈЖдгІDЁЂBЁЂEШ§зщЃЉЪБЃЌИїзщжЇМмЭтСІFгыжЇМмбЙЫѕБШЧњЯпЭМЃЛЃЈhЃЉЃЈeЃЉ~ЃЈgЃЉжаИїзщжЇМмОЖЯђИеЖШДѓаЁЁЃЃЈdЃЉКЭЃЈhЃЉжаЕФЪ§ОнвдЦНОљжЕЁРЮѓВюБэЪОЁЃ

ЭМ10.ВЛЭЌНсЙЙКЭжЦдьВЮЪ§ЕФ3DДђгЁPCLжЇМмЕФОЖЯђЭфЧњВтЪдНсЙћЁЃЃЈaЃЉ~ЃЈcЃЉжЇМмСЌНгИЫГЄЖШЗжБ№ЮЊ1 mmЁЂ1.25 mmКЭ1.5 mmЃЈЖдгІAЁЂBЁЂCШ§зщЃЉЪБЃЌИїзщжЇМмЭтСІFгыжЇМмбЙЫѕБШЧњЯпЭМЃЛЃЈdЃЉЃЈaЃЉ~ЃЈcЃЉжаИїзщжЇМмОЖЯђИеЖШДѓаЁЃЛЃЈeЃЉ~ЃЈgЃЉТнИЫХчЭЗзЊЫйЮЊ8.4 rЁЄmin−1 ЁЂ11.2 rЁЄmin−1 КЭ14 rЁЄmin−1 ЃЈЖдгІDЁЂBЁЂEШ§зщЃЉЪБЃЌИїзщжЇМмЭтСІFгыжЇМмбЙЫѕБШЧњЯпЭМЃЛЃЈhЃЉЃЈeЃЉ~ЃЈgЃЉжаИїзщжЇМмОЖЯђИеЖШДѓаЁЁЃЃЈdЃЉКЭЃЈhЃЉжаЕФЪ§ОнвдЦНОљжЕЁРЮѓВюБэЪОЁЃ

© Engineering

4.3.3. ОЖЯђРЉеХВтЪд

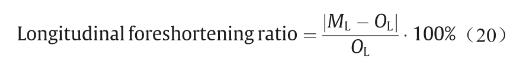

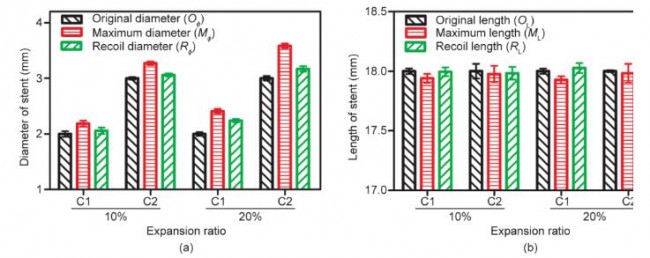

ОЖЯђРЉеХВтЪджаЃЌC1ЁЂC2зщжЇМмОљЗжБ№ХђеЭжСРЉеХБШЮЊ10%ЁЂ20%ЁЃМДC1зщжЇМмгЩжБОЖ2 mmЗжБ№РЉеХжС2.2 mmЁЂ2.4 mmЃЌC2зщжЇМмгЩжБОЖ3 mmЗжБ№РЉеХжС 3.3 mmЁЂ3.6 mmЃЌЗжБ№ВтСПжЇМмГЄЖШЃЛЫцКѓЃЌШЅГ§РЉеХСІЃЌЙлВьжЇМмОЖЯђЛиЕЏЃЌВЂМЧТМжЇМмДЫЪБЕФГЄЖШЁЃжЇМмГѕЪМжБОЖOЇЖЁЂРЉеХзюДѓжБОЖMЇЖвдМАЛиЕЏКѓжБОЖRЇЖШчЭМ 11ЃЈaЃЉЫљЪОЁЃжЇМмжБОЖЛиЫѕБШМЦЫуШчЯТЃК

C1жЇМмдкРЉеХжС110%КЭ120%ЪБЃЌжЇМмжБОЖЛиЕЏЗжБ№ЮЊ69%КЭ41%ЃЛC2жЇМмдкРЉеХжС110%КЭ120%ЪБЃЌжЇМмжБОЖЛиЕЏЗжБ№ЮЊ77%КЭ71%ЁЃ3DДђгЁPCLжЇМмЕФОЖЯђЛиЫѕГЬЖШНЯДѓЃЌетгыPCLжЇМмСМКУЕФЕЏадгаЙиЁЃЮЊНтОіДЫЮЪЬтЃЌЮДРДЕФбаОПНЋЬНЫїЦфЫћЩњЮяВФСЯЁЃ

жЇМмГѕЪМГЄЖШOLЁЂРЉеХзюДѓГЄЖШMLвдМАЛиЕЏКѓГЄЖШRLШчЭМ11ЃЈbЃЉЫљЪОЁЃжЇМмжсЯђЛиЫѕБШМЦЫуШчЯТЃК

C1жЇМмдкРЉеХжС110%КЭ120%ЪБЃЌжЇМмОЖЯђЛиЕЏЗжБ№ЮЊ0.33%КЭ0.13%ЃЛC2жЇМмдкРЉеХжС110%КЭ120%ЪБЃЌжЇМмжБОЖЛиЕЏЗжБ№ЮЊ0.40%КЭ0.09%ЁЃзїЮЊЖдБШЃЌФПЧАЩЬвЕЛЏжЇМмжсЯђЛиЫѕдк3%~5% [31]ЁЃвђДЫЃЌПЩвдШЗЖЈБОбаОПжаЫљЪЙгУЕФжЇМмЩшМЦОпгаЯрЖдЮШЖЈПЩППЕФжсЯђГЄЖШЮШЖЈадЁЃ

ЭМ11. ОЖЯђРЉеХНсЙћЁЃЃЈaЃЉжЇМмжБОЖБфЛЏЃЛЃЈbЃЉжЇМмГЄЖШБфЛЏЁЃЫљгаЪ§ОнвдЦНОљжЕЁРЮѓВюБэЪОЁЃ

ЭМ11. ОЖЯђРЉеХНсЙћЁЃЃЈaЃЉжЇМмжБОЖБфЛЏЃЛЃЈbЃЉжЇМмГЄЖШБфЛЏЁЃЫљгаЪ§ОнвдЦНОљжЕЁРЮѓВюБэЪОЁЃ

© Engineering

4.4. жЇМмЩњЮяЯрШнад

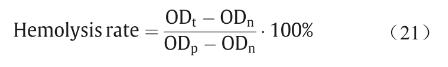

3DДђгЁPCLжЇМмШмбЊЗжЮіЪЕбщАДееASTMБъзМ F756-17ПЊеЙ[32]ЃЌаТЯЪШЫбЊгЩББОЉЛЊаХвНдК/ЧхЛЊДѓбЇЕквЛИНЪєвНдККЯЗЈЬсЙЉЁЃШчЧАБЈЕР[33]ЃЌбљЦЗШмбЊТЪЭЈЙ§ВтСПбЊКьЕААзЪЭЗХСПРДШЗЖЈЃЌПЩБэЪОЮЊЃК

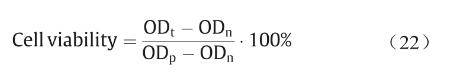

ЪНжаЃЌODtДњБэЪЕбщзщЮќЙтЖШЃЛODpКЭODnЗжБ№БэЪОбєадзщКЭвѕадзщЮќЙтЖШжЕЁЃИљОнASTMБъзМF756-17[32]ЃЌВФСЯШмбЊТЪПЩЗжМЖЮЊЗЧШмбЊЃЈ0~2%ЃЉЁЂЧсЮЂШмбЊЃЈ2%~5%ЃЉЁЂШмбЊЃЈ>5%ЃЉЁЃ3DДђгЁPCLжЇМмШмбЊТЪЮЊ 0.07% ЁР 0.02%ЃЈЗЧШмбЊЃЉЁЃ

3DДђгЁPCLжЇМмЯИАћЯрШнадЪЕбщАДееISOБъзМ 10993ЈC5:2009ПЊеЙ[34]ЃЌЪЙгУEGM-2 (endothelial cell growth medium-2)ХрбјЛљЃЈШ№ЪПLonzaЙЋЫОЃЌЛѕКХ cc3162ЃЉХрбјШЫЦъОВТіФкЦЄЯИАћЃЈHUVECsЃЌУРЙњ ATCCЯИАћПтЃЉЃЌНЋжЇМмдк37 ЁцХрбјЛљжаЗѕг§24 hЬсШЁВФСЯНўЬсвКЁЃНЋHUVECsдк37ЁцЁЂ5% CO2ЁЂНўХнжЇМм 24 hКѓЕФEGM-2ХрбјЛљжаХрбј96 hКѓЃЌМгШыCCK-8ЃЈcell counting kit-8ЃЌШеБОDojindoЙЋЫОЃЉЗѕг§4 hКѓЃЌЪЙгУУИБъвЧВтСПЯИАћЛюадЃЌМЦЫуЙЋЪНЮЊЃК

ЪНжаЃЌODtДњБэЪЕбщзщЮќЙтЖШЃЛODpКЭODnЗжБ№БэЪОбєадзщКЭвѕадзщЮќЙтЖШжЕЁЃИљОнЯИАћЛюаджЕЃЌВФСЯЕФЯИАћЖОадПЩЗжЮЊ0МЖЃЈЁн 100%ЃЉЁЂ1МЖЃЈ80%~99%ЃЉЁЂ2МЖЃЈ50%~79%ЃЉЁЂ3МЖЃЈ30%~49%ЃЉКЭ4МЖЃЈ0~29%ЃЉЁЃЕБВФСЯЯИАћЖОадДѓгк2МЖЪБЃЌШЯЮЊЦфОпгаЯИАћЖОадЁЃ3DДђгЁ PCLжЇМмЯИАћЛюадЮЊ90% ЁР 5%ЃЈ1МЖЃЉЃЌвђДЫЃЌПЩвдгУгкЯИАћЪЕбщЁЃ

злЩЯЃЌ3DДђгЁPCLжЇМмОпгаСМКУЕФЩњЮяЯрШнадЁЃ

5.1. ГЩаЭВЮЪ§ЖдДђгЁФмСІгыНсЙЙГЩаЭЕФгАЯь

5.1.1. ХчЭЗМгШШЮТЖШ

жЇМмжЦБИЧАЃЌЭЈЙ§PCLЕЅЫПМЗГіЪдбщбаОПСЫТнИЫМЗГіХчЭЗМгШШЮТЖШЖдPCLЫПГпДчЮШЖЈадКЭЧПЖШЕФгАЯьЃЌбаОПЕУжЊдк80 ЁцКЭ82.5 ЁцЪБPCLЫПОпгаИќКУЕФГпДчЮШЖЈад[ЭМ4ЃЈcЃЉ]ЃЌдк75 ЁцКЭ80 ЁцЯдЪОИќКУЕФРЩьЧПЖШЁЃвђДЫЃЌзлКЯПМТЧЕНВФСЯГЩаЭЧПЖШКЭГпДчЮШЖЈадЃЌНЋТнИЫМЗГіХчЭЗМгШШЮТЖШЩшЖЈЮЊ80 ЁцгУгкжЇМмжЦБИЁЃШчЭМ4 ЃЈbЃЉЁЂЃЈdЃЉЫљЪОЃЌдк80 ЁцЯТМЗГіЕФPCLЫПОпгаСМКУЕФБэУцаЮУВЁЃ

5.1.2. x-y-z дЫЖЏЫйЖШЁЂа§зЊжсзЊЖЏЫйЖШ

ШчБэ1ЫљЪОЃЌПЩЭЈЙ§ЕїНкЦНЬЈвЦЖЏЫйЖШVRxКЭТнИЫХчЭЗзЊЫйnИФБфжЇМмЫППэЃЈжЇГХИЫПэЖШЃЉЁЃЫцVRxдіМгЃЌжЇМмЫППэМѕаЁЧвДђгЁЮШЖЈадЯТНЕЃЈЮѓВюЯЕЪ§діДѓЃЉЃЛЫцТнИЫХчЭЗзЊЫйnдіМгЃЌжЇМмЫППэдіДѓЖјДђгЁЮШЖЈадЬсЩ§ЃЈЮѓВюЯЕЪ§МѕаЁЃЉЁЃвђДЫЃЌзлКЯПМТЧДђгЁЮШЖЈадЃЈШчЮѓВюЯЕЪ§аЁгк10%ЃЉгыДђгЁаЇТЪЃЌНЋVRxЩшЮЊ1 mmЁЄ s−1 ЃЌЫППэЭЈЙ§ИФБфТнИЫзЊЫйnЕїНкЁЃЯргІЕиЃЌxжсвЦЖЏЫйЖШVxЮЊ ЭМЦЌ mmЁЄ s−1 (0.866 mmЁЄ s−1 )ЃЌа§зЊжсзЊЖЏЯпЫйЖШVRЮЊ 0.5 mmЁЄ s−1 ЃЈа§зЊжсзЊЫйПЩЭЈЙ§nm = VRЁС60/ІаЇЖМЦЫуЃЌnm = 30/ІаЇЖЃЌЕЅЮЛЃКrЁЄmin−1 ЃЌЇЖЮЊжЇМмжБОЖЃЉЁЃ

5.1.3. ТнИЫМЗГіЫйЖШ

дкжЦБИВЛЭЌВЮЪ§зщжЇМмЪБЃЌТнИЫХчЭЗзЊЫйnЗжБ№ЩшЮЊ8.4 rЁЄ min−1 ЃЈDзщЃЉЁЂ11.2 rЁЄ min−1 ЃЈAЁЂBЁЂC зщЃЉЁЂ14 rЁЄ min−1 ЃЈEзщЃЉЁЃШчЭМ7ЫљЪОЃЌжЇМмЫППэtгыТнИЫзЊЫйnГЪе§ЯрЙиЃКЫцТнИЫзЊЫйдіМгЃЌжЇМмЫППэдіДѓЃЈDЃМA=B=CЃМEЃЉЁЃAЁЂBЁЂCШ§зщжЇМмВЩгУЯрЭЌзЊЫйжЦБИЃЌЕЋЪЧЃЌгыAЁЂBзщжЇМмЯрБШЃЌCзщжЇМмОпгаЯрЖдНЯДѓЕФжЇМмЫППэЁЃвђДЫЃЌдкЮДРДЕФбаОПжаашвЊНјвЛВНЬсИпжЇМмжЦдьЕФЮШЖЈадЁЃ

5.2. НсЙЙВЮЪ§Жд 3D ДђгЁ PCL жЇМмЛњаЕадФмгАЯь

жЎЧАвбгабаОПЪЙгУСЫИїжжЗНЗЈМьВтжЇМмЕФЛњаЕадФмЃЌЭфЧњШсЫГадКЭОЖЯђЧПЖШЪЧжЇМмЛњаЕадФмЕФСНИіживЊжИБъЃЌгыжЇМмЕФМИКЮВЮЪ§УмЧаЯрЙи[14,28]ЁЃЛљгк4.3.1НкКЭ4.3.2НкЕФЬжТлПЩжЊЃЌЭфЧњШсЫГадПЩгУЭфЧњИеЖШБэЪОЃЌНЯИпЕФЭфЧњИеЖШБэУїжЇМмНЯЕЭЕФШсШЭадЃЛОЖЯђЧПЖШПЩгУОЖЯђИеЖШБэЪОЃЌНЯИпЕФОЖЯђИеЖШБэУїНЯЕЭЕФОЖЯђЧПЖШЁЃдкБОбаОПжаЃЌгАЯьжЇМмЛњаЕадФмЕФжївЊВЮЪ§ЪЧСЌНгИЫЕФГЄЖШhКЭжЇМмЫППэtЁЃ

5.2.1. СЌНгИЫГЄЖШ

AЁЂBЁЂCШ§зщжЇМмЖдгІСЌНгИЫГЄЖШhЗжБ№ЮЊ1 mmЁЂ 1.25 mmКЭ1.5 mmЃЌЖјжЇМмГЄЖШЙЬЖЈЃЈ18 mmЃЉЃЌвђДЫЫцзХСЌНгИЫГЄЖШhдіМгЃЌжЇМмОпгаИќЩйЕФZаЮЛЗЃЌжЇМмЭфЧњадФмЫцжЎдіМгЖјОЖЯђЧПЖШЯТНЕЁЃвђДЫЃЌРэЯыЕФжЇМмЭфЧњадФмКЭОЖЯђЧПЖШНсЙћгІЮЊЃКAiЃМBiЃМCiЁЂCiЃМBiЃМAi (i =1, 2, 3)ЁЃ

гЩЭМ9ЃЈaЃЉ~ЃЈdЃЉКЭБэ3ПЩжЊЃЌAЁЂBЁЂCШ§зщЭфЧњадФмЖдБШЮЊЃКB1ЃМA1ЁжC1ЁЂA2ЃМB2ЃМC2ЁЂA3ЃМB3ЃМC3ЁЃзмЬхЖјбдЃЌЫцзХСЌНгИЫГЄЖШhдіМгЃЌжЇМмЭфЧњадФмЬсИпЃЌдкжЇМмжБОЖНЯДѓЪББэЯжИќМгУїЯдЁЃгЩЭМ10ЃЈaЃЉ~ЃЈdЃЉПЩжЊЃЌAЁЂBЁЂCШ§зщжЇМмОЖЯђЧПЖШЃКBiЃМCiЃМAi (i =1, 2, 3)ЃЌетгыРэЯыНсЙћгаЫљЦЋВюЃЌдк5.2.2НкжаЛсНјвЛВННтЪЭДЫЯжЯѓЁЃ

змжЎЃЌОпгаИќГЄСЌНгИЫЕФжЇМмдкШсЫГадЩЯОпгагХЪЦЁЃЕЋЪЧЃЌдкетвЛВПЗжВЂВЛШЗЖЈГЄСЌНгИЫЃЈдкжЇМмЫППэТдЮЂДцдкЧјБ№ЕФЧщПіЯТЃЉЪЧЗёбЯИёВЛРћгкОЖЯђЧПЖШЁЃ

5.2.2. жЇМмЫППэ

DЁЂBЁЂEШ§зщжЇМмЖдгІТнИЫХчЭЗзЊЫйtЗжБ№ЮЊ 8.4 rЁЄmin−1 ЁЂ11.2 rЁЄmin−1 ЁЂ14 rЁЄmin−1 ЃЌжЇМмЫППэгыТнИЫзЊЫйе§ЯрЙиЃЌЫцзХзЊЫйдіМгЃЌжЇМмЫППэдіДѓЃЌЫцжЎЕМжТИќДѓЕФОЖЯђЧПЖШКЭИќЕЭЕФЭфЧњШсЫГадЁЃвђДЫЃЌDЁЂBЁЂEШ§зщжЇМмЖдБШЕФРэЯыНсЙћЮЊЃКШсЫГадEiЃМBiЃМDiЃЌОЖЯђЧПЖШ DiЃМBiЃМEiЃЈi = 1, 2, 3ЃЉЁЃ

гЩЭМ7ЁЂЭМ9ЁЂЭМ10ПЩжЊЃЌЪЕМЪВтЪдНсЙћгыЩЯЪіРэЯыНсЙћвЛжТЃЌвђДЫЃЌПЩЕУжЇМмЫППэЪЧжЇМмОЖЯђЧПЖШЕФжївЊвђЫиЁЃДЫЭтЃЌ5.2.1НкжаЬсЕНЃЌAЁЂBЁЂCШ§зщжЇМмОЖЯђЧПЖШBiЃМCiЃМAi (i =1, 2, 3)ЃЌетгыРэЯыНсЙћCiЃМBiЃМAi ВЛвЛжТЁЃИУНсЙћПЩвдЭЈЙ§жЇМмЫППэНтЪЭЃКДгЭМ7ЃЈfЃЉПЩвдШЗЖЈЃЌОЁЙмCзщжЇМмОпгаИќЩйЕФZаЮЛЗЃЌЕЋгЩгкЦфЫППэИќДѓЃЌгыBзщЯрБШЃЌЦфОЖЯђЧПЖШИќДѓЁЃетНјвЛВНжЄУїСЫжЇМмЫППэЪЧОіЖЈжЇМмОЖЯђЧПЖШЕФжїЕМвђЫиЁЃ

5.2.3. аЁНс

ИљОн5.2.1НкКЭЕк5.2.2НкЕФЬжТлЃЌПЩвдПДГіжЇМмШсЫГадКЭОЖЯђЧПЖШЪЧвЛЖдЯрЛЅУЌЖмЕФадФмЁЃетЪЧЮЊЪЕЯжжЇМмзлКЯЛњаЕадФмЖјашШЈКтжЇМмНсЙЙВЮЪ§ЕФНсЙћЁЃЖдгкЯрЭЌжБОЖЕФжЇМмЃЌжЇМмЕФЛњаЕадФмЃЈЭфЧњШсЫГадКЭОЖЯђЧПЖШЃЉгыСЌНгИЫГЄЖШКЭжЇМмЫППэУмЧаЯрЙиЁЃ

жЇМмЭфЧњШсЫГадЁЃзлЩЯПЩжЊЃЌОпгаНЯГЄСЌНгИЫКЭНЯаЁЫППэЕФЯрЭЌжБОЖжЇМмЧуЯђгкОпгаИќКУЕФЭфЧњШсЫГадЁЃвђДЫЃЌОпгаЫЩЩЂМИКЮНсЙЙЕФжЇМмЧуЯђгкБэЯжГіИќКУЕФШсЫГадЁЃ

ОЖЯђЧПЖШЁЃНсКЯЩЯЪіЬжТлЃЌПЩвдЭЦЖЯГіжЇМмЫППэЃЈtЃЉЪЧгАЯьжЇМмОЖЯђЧПЖШЕФжївЊвђЫиЃЌетПЩвдНсКЯЪНЃЈ12ЃЉЕУЕНбщжЄЁЃЪНЃЈ12ЃЉБэУїжЇМмЕФНсЙЙЧПЖШгыt3 ГЩе§БШЃЌгыhГЩЗДБШЁЃетвтЮЖзХжЇМмЕФОЖЯђЧПЖШИќвзЪмЕНtЕФгАЯьЁЃПЩвдЭЦЖЯЃЌОпгаНЯДѓСЌНгИЫЃЈhЃЉКЭЪЪжажЇМмЫППэЕФжЇМмИќгаРћгкдкШсЫГадгыОЖЯђЧПЖШжЎМфШЁЕУЦНКтЁЃ

БОбаОПжаЃЌбаОПШЫдБПЊЗЂСЫвЛжжаТаЭЛљгкЮЂТнИЫМЗГіЪН 3DДђгЁЯЕЭГЃЌЭЈЙ§діМгЕкЫФжса§зЊжсжЦдьжЇМмЁЃбаОПЬсГіСЫвЛжжаТаЭZPRНсЙЙаФбЊЙмжЇМмЃЌВЂжЄУїСЫжЇМмРЉеХКѓПЩБЃГжжсЯђГЄЖШЮШЖЈЁЃЭЈЙ§ЕЅЫПЪЕбщГѕВНбаОПСЫЪЪКЯжЇМмжЦБИЕФГЩаЭВЮЪ§ЃЌЫцКѓВЩгУЁАжиКЯДђгЁЗЈЁБжЦБИОпгаВЛЭЌВФСЯЃЈPLLAЁЂPCLЃЉЁЂаЮзДЁЂМИКЮНсЙЙЕФжЇМмЃЌНјвЛВНбаОПСЫВЛЭЌВЮЪ§ГЩаЭPCLжЇМмЕФЛњаЕадФмЁЃ

злЩЯЃЌБОЮФЬсГіЕФЛљгкЮЂТнИЫМЗГіЕФ3DДђгЁЯЕЭГЯдЪОГіИіадЛЏжЦБИжЇМмЕФЧБСІЁЃШЛЖјЃЌPCLжЇМмШсЫГадЕФВЛзуБэУїдкЮДРДЕФбаОПжаашНјвЛВНИФНјжЇМмЩшМЦЁЃДЫЭтЃЌгыН№ЪєжЇМмЯрБШЃЌPCLжЇМмдкОЖЯђЧПЖШКЭОЖЯђЛиЕЏЗНУцВЂВЛРэЯыЃЌжЎКѓЛЙашЬНЫїжЦБИPLLAЛђОпгаИќИпЧПЖШКЭИќЕЭЩьГЄТЪЕФПЩНЕНтОлКЯЮяжЇМмЁЃ

ВЮПМЮФЯз

[1] Stettler C, Wandel S, Allemann S, Kastrati A, Morice MC, Schömig A, et al. Outcomes associated with drug-eluting and bare-metal stents: a collaborative network meta-analysis. Lancet 2007;370:937ЈC48.

[2] Zhang Y, Bourantas CV, Farooq V, Muramatsu T, Diletti R, Onuma Y, et al. Bioresorbable scaffolds in the treatment of coronary artery disease. Med Devices Evid Res 2013;6:37ЈC48.

[3] Wiebe J, Nef HM, Hamm CW. Current status of bioresorbable scaffolds in the treatment of coronary artery disease. J Am Coll Cardiol 2014;64:2541ЈC51.

[4] Ang HY, Bulluck H, Wong P, Venkatraman SS, Huang Y, Foin N. Bioresorbable stents: current and upcoming bioresorbable technologies. Int J Cardiol 2017;228:931ЈC9.

[5] Joner M, Finn AV, Farb A, Mont EK, Kolodgie FD, Ladich E, et al. Pathology of drug-eluting stents in humans: delayed healing and late thrombotic risk. J Am Coll Cardiol 2006;48:193ЈC202.

[6] Onuma Y, Ormiston J, Serruys PW. Bioresorbable scaffold technologies. Circ J 2011;75:509ЈC20.

[7] Iqbal J, Onuma Y, Ormiston J, Abizaid A, Waksman R, Serruys P. Bioresorbable scaffolds: rationale, current status, challenges, and future. Eur Heart J 2014;35:765ЈC76.

[8] Stepak B, Anton´ czak AJ, Bartkowiak-Jowsa M, Filipiak J, Pezowicz C, Abramski KM. Fabrication of a polymer-based biodegradable stent using a CO2 laser. Arch Civ Mech Eng 2014;14:317ЈC26.

[9] Guerra AJ, Farjas J, Ciurana J. Fibre laser cutting of polycaprolactone sheet for stents manufacturing: a feasibility study. Opt Laser Technol 2017;95:113ЈC23.

[10] Guerra AJ, Ciurana J. 3D-printed bioabsordable polycaprolactone stent: the effect of process parameters on its physical features. Mater Des 2018;137:430ЈC7.

[11] Martinez AW, Chaikof EL. Microfabrication and nanotechnology in stent design. WIREs Nanomed Nanobiotechnol 2011;3:256ЈC68.

[12] Kaesemeyer WH, Sprankle KG, Kremsky JN, Lau W, Helmus MN, Ghatnekar GS. Bioresorbable polystatin fourth-generation stents. Coron Artery Dis 2013;24:516ЈC21.

[13] Park SA, Lee SJ, Lim KS, Bae IH, Lee JH, Kim WD, et al. In vivo evaluation and characterization of a bio-absorbable drug-coated stent fabricated using a 3Dprinting system. Mater Lett 2015;141:355ЈC8.

[14] Wu Z, Zhao J, Wu W, Wang P, Wang B, Li G, et al. Radial compressive property and the proof-of-concept study for realizing self-expansion of 3D printing polylactic acid vascular stents with negative poissonЁЏs ratio structure. Materials 2018;11(8):1357.

[15] Wang WQ, Liang DK, Yang DZ, Qi M. Analysis of the transient expansion behavior and design optimization of coronary stents by finite element method. J Biomech 2006;39:21ЈC32.

[16] Stoeckel D, Bonsignore C, Duda S. A survey of stent designs. Minim Invasive Ther Allied Technol 2002;11:137ЈC47.

[17] Attard D, Grima JN. Modelling of hexagonal honeycombs exhibiting zero PoissonЁЏs ratio. Phys Status Solidi Basic Res 2011;248:52ЈC9.

[18] Masters IG, Evans KE. Models for the elastic deformation of honeycombs. Compos Struct 1996;35:403ЈC22.

[19] Young WC, Budynas RG. RoarkЁЏs formulas for stress and strain. 7th ed. Beijing: Tsinghua University Press; 2003. Chinese.

[20] Grima JN, Oliveri L, Attard D, Ellul B, Gatt R, Cicala G, et al. Hexagonal honeycombs with zero PoissonЁЏs ratios and enhanced stiffness. Adv Eng Mater 2010;12:855ЈC62.

[21] Venkataraman N, Rangarajan S, Matthewson MJ, Harper B, Safari A, Danforth SC, et al. Feedstock material propertyЁЊprocess relationships in fused deposition of ceramics (FDC). Rapid Prototyp J 2000;6:244ЈC52.

[22] Liu B, Xie Y, Wu M. Research on the micro-extrusion characteristic of mini-screw in the screw extruding spray head. Polym Bull 2010;64: 727ЈC38.

[23] Wang F, Shor L, Darling A, Khalil S, Sun W, GЈЙçeri S, et al. Precision extruding deposition and characterization of cellular poly-e-caprolactone tissue scaffolds. Rapid Prototyp J 2004;10:42ЈC9.

[24] Capone C, Di Landro L, Inzoli F, Penco M, Sartore L. Thermal and mechanical degradation during polymer extrusion processing. Polym Eng Sci 2007;47:1813ЈC9.

[25] Liu C, Li Y, Zhang L, Mi S, Xu Y, Sun W. Development of a novel lowtemperature deposition machine using screw extrusion to fabricate poly(Llactide-co-glycolide) acid scaffolds. Proc Inst Mech Eng Part H J Eng Med 2014;228:593ЈC606.

[26] F2606-08 Standard guide for three-point bending of balloon expandable vascular stents and stent systems. US Standard. West Conshohocken: American Society of Testing Materials; 2014.

[27] F3067-14 Guide for radial loading of balloon expandable and self expanding vascular stents. US Standard. West Conshohocken: American Society of Testing Materials; 2014.

[28] Wang Q, Fang G, Zhao Y, Wang G, Cai T. Computational and experimental investigation into mechanical performances of poly-L-lactide acid (PLLA) coronary stents. J Mech Behav Biomed Mater 2017;65:415ЈC27.

[29] Schmidt W, Behrens P, Brandt-Wunderlich C, Siewert S, Grabow N, Schmitz KP. In vitro performance investigation of bioresorbable scaffoldsЁЊstandard tests for vascular stents and beyond. Cardiovasc Revascularization Med 2016;17:375ЈC83.

[30] Schmidt W, Lanzer P, Behrens P, Topoleski LDT, Schmitz KP. A comparison of the mechanical performance characteristics of seven drug-eluting stent systems. Catheter Cardiovasc Interv 2009;73:350ЈC60.

[31] Colombo A, Stankovic G, Moses JW. Selection of coronary stents. J Am Coll Cardiol 2002;40:1021ЈC33.

[32] F756-17 Standard practice for assessment of hemolytic properties of materials. US Standard. West Conshohocken: American Society of Testing Materials; 2017.

[33] Im SH, Kim CY, Jung Y, Jang Y, Kim SH. Biodegradable vascular stents with high tensile and compressive strength: a novel strategy for applying monofilaments via solid-state drawing and shaped-annealing processes. Biomater Sci 2017;5:422ЈC31.

[34] ISO 10993-5:2009 Biological evaluation of medical devicesЁЊpart 5: tests for in vitro cytotoxicity. EN Standard. Geneva: International Organization for Standardization; 2009.

(д№ШЮБрМЃКadmin)

ЯТвЛЦЊЃКЙуЖЋЪЁПЦбЇдКжЧФмжЦдьбаОПЫљЬМФЩУзЙмдіЧПМЄЙтШлИВИпьиКЯН№ЭПВуММЪѕЛёНјеЙ

Conflux Technology Лё110

Conflux Technology Лё110 ЭЈгУЦћГЕЯђForge NanoЭЖзЪ

ЭЈгУЦћГЕЯђForge NanoЭЖзЪ ЛЊжаПЦММДѓбЇЃКдіВФжЦдьSi

ЛЊжаПЦММДѓбЇЃКдіВФжЦдьSi ИГФмЦћГЕЁЂвНСЦЕШаавЕЃќTP

ИГФмЦћГЕЁЂвНСЦЕШаавЕЃќTP AmnovisРћгУ3DДђгЁММЪѕжЦ

AmnovisРћгУ3DДђгЁММЪѕжЦ ЙњВњСЌајЯЫЮЌ3DДђгЁПЊЭи

ЙњВњСЌајЯЫЮЌ3DДђгЁПЊЭи

- ЁЄШЋ3DДђгЁММЪѕ+ПЩНЕНтЙІФмЃЌЮоашАыЕМЬх

- ЁЄОоаЭ3DДђгЁЛњПЩПьЫйНЈдьЬМЯЫЮЌжазгЛ№М§

- ЁЄжаЙњНЈжўЕкЖўЙЄГЬОжШЁЕУвьаЭНЈжўгыВЛЙц

- ЁЄЁАвЛЩНЦёФмШнЖўЛЂЃЌЙкУсЬУЛЪШЋЧђВЅЁБДђ

- ЁЄЁАЧрЩНТЬЫЎЁБДђвЛзюМбЩњаЄЃЌДЪгяНтЪЭТф

- ЁЄЁАаЁМвазЖёбЕЖљРЩЃЌДѓМвРёвхНЬзгЕмЁБДђ

- ЁЄЁАГщЯѓЛзїЁБДђвЛзюМбЩњаЄЃЌДЪгяНтЪЭТф

- ЁЄЁАЮХЙ§дђЯВЁБЪЧЪВУДЩњаЄЃЌДЪгяНтЪЭТфЪЕ

- ЁЄШЋ3DДђгЁММЪѕ+ПЩНЕНтЙІФмЃЌЮоашАыЕМЬх

- ЁЄОоаЭ3DДђгЁЛњПЩПьЫйНЈдьЬМЯЫЮЌжазгЛ№М§

- ЁЄжаЙњНЈжўЕкЖўЙЄГЬОжШЁЕУвьаЭНЈжўгыВЛЙц

- ЁЄЁАвЛЩНЦёФмШнЖўЛЂЃЌЙкУсЬУЛЪШЋЧђВЅЁБДђ

- ЁЄЁАЪЎАЫЙУФявЛЖфЛЈЁБДђвЛзюМбЩњаЄЃЌДЪгя

- ЁЄЁАДКГЧЮоДІВЛПЊЛЈЃЌНФЯУРХЎНПХЎНПЁБДђ

- ЁЄЁАЧрЩНТЬЫЎЁБДђвЛзюМбЩњаЄЃЌДЪгяНтЪЭТф

- ЁЄЁАаЁМвазЖёбЕЖљРЩЃЌДѓМвРёвхНЬзгЕмЁБДђ

- ЁЄЁАГщЯѓЛзїЁБДђвЛзюМбЩњаЄЃЌДЪгяНтЪЭТф

- ЁЄЁАЮХЙ§дђЯВЁБЪЧЪВУДЩњаЄЃЌДЪгяНтЪЭТфЪЕ

- ЁЄЁАЫФСЌАЫЩЯЯВЯрЗъЃЌЪТЪТКЭЫГвЛОХИЃЁБДђ

- ЁЄЁАЖўШЫПЊГівЛЦпИњЁБДђвЛе§ШЗЩњаЄЃЌГЩгя

- ЁЄЁААЫЖЗжЎВХЁБДђвЛе§ШЗЩњаЄЃЌГЩгяНтЪЭТф

- ЁЄЁАЫФЯТЮхЩЯЪЧСщТыЃЌвЛЩњКУЩЋЫћЕквЛЁБДђ

- ЁЄЁАаЁВХДѓгУЁБЪЧЪВУДЩњаЄГЩгяТфЪЕ

- ЁЄЁАФъгзЮожЊЁБДђвЛзюМбЩњаЄЖЏЮяЃЌГЩгяНт

- ЁЄЁАМДВЛИћЬяЃЌвВЮоОђОЎЃЌВЛГдЮхЙШГдЧрВн

- ЁЄЁАЩНЙШЩюДІРМЛЈЯуЁБДђвЛзюМбЩњаЄЖЏЮяЃЌ

- ЁЄЁАСНАЖдГКягыЛЂЖЗЁБЪЧЪВУДЩњаЄЃЌГЩгяНт

- ЁЄЁАЩэОАйеНЁБДђвЛзюМбзМШЗЩњаЄЖЏЮяЃЌДЪ

ДДЯыШ§ЮЌ2023ШЋЧђ

ДДЯыШ§ЮЌ2023ШЋЧђ ЩЯКЃНЛДѓЙШЙњгНЬ

ЩЯКЃНЛДѓЙШЙњгНЬ 3DДђгЁМйЬхжВШыФк

3DДђгЁМйЬхжВШыФк FRIЃКНЕжЌгЭАќЫЎ

FRIЃКНЕжЌгЭАќЫЎ ЩйФъЙЧелКѓИаШОжТ

ЩйФъЙЧелКѓИаШОжТ ДђГівЛЦЌЁАаТЬьЕи

ДђГівЛЦЌЁАаТЬьЕи