改性淀粉基油墨的3D打印适性及其形成机制研究:在冰淇淋中的应用

时间:2024-04-26 09:05 来源:食品科学 作者:admin 阅读:次

传统冰淇淋不适合 3D 打印进行个性化加工。因此,本研究选择变性淀粉来增强冰淇淋3D打印的可行性。我们根据油墨的稳定性和流变特性,从含有13种变性淀粉的冰淇淋中选择了7种油墨来研究3D打印冰淇淋的成型机理。用羟丙基二淀粉磷酸酯(HDSP)制备的冰淇淋墨水表现出最高的精度(94.6%),这归因于墨水中存在更多的氢键支撑和稳定的蛋白质结构。这些分子间相互作用导致优异的保水性并形成致密的凝胶结构,进一步增强了墨水的弹性、结构恢复率(99.66%)和机械性能(1896.35Pa)。这些增强的性能有助于在3D打印过程中挤出更细的线宽(0.95毫米),并提高打印产品的自支撑能力,从而提高3D打印冰淇淋的精度。进一步分析打印产品的质感特性,可以全面评估变性淀粉在3D打印冰淇淋中的应用潜力。这项研究为使用淀粉材料个性化生产冰淇淋提供了新颖的见解。

研究结果:

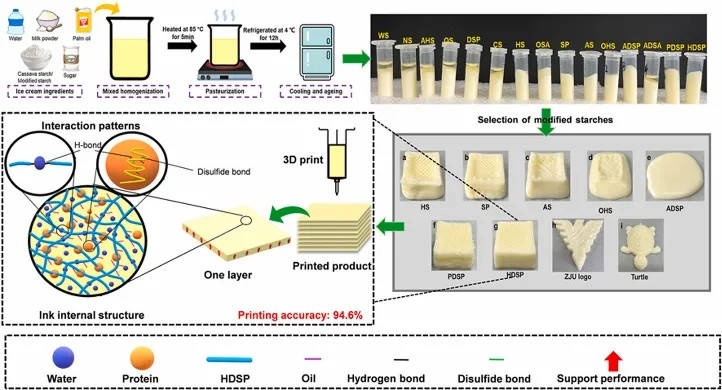

3.1. 冰淇淋油墨的稳定性

Fig. 1. Preparation of ice cream ink with different

modified starches for 3D printing. (a) Ice cream ink preparation

process; (b) Ice cream ink stability test; (c) Ice cream ink layering

distribution; (d) Ice cream ink oil-holding capacity; (e) Ice cream ink

sedimentation rate.

3.2. 冰淇淋油墨的流变特性

Fig. 2. Rheological properties of ice cream inks

with different modified starches. (a) Dynamic viscosity profile; (b)

Frequency scanning profile (G′); (c) Frequency scanning profile (G″);

(d) Influence of ice cream components on dynamic viscosity of inks; (e)

Influence of ice cream components on elastic modulus of inks.

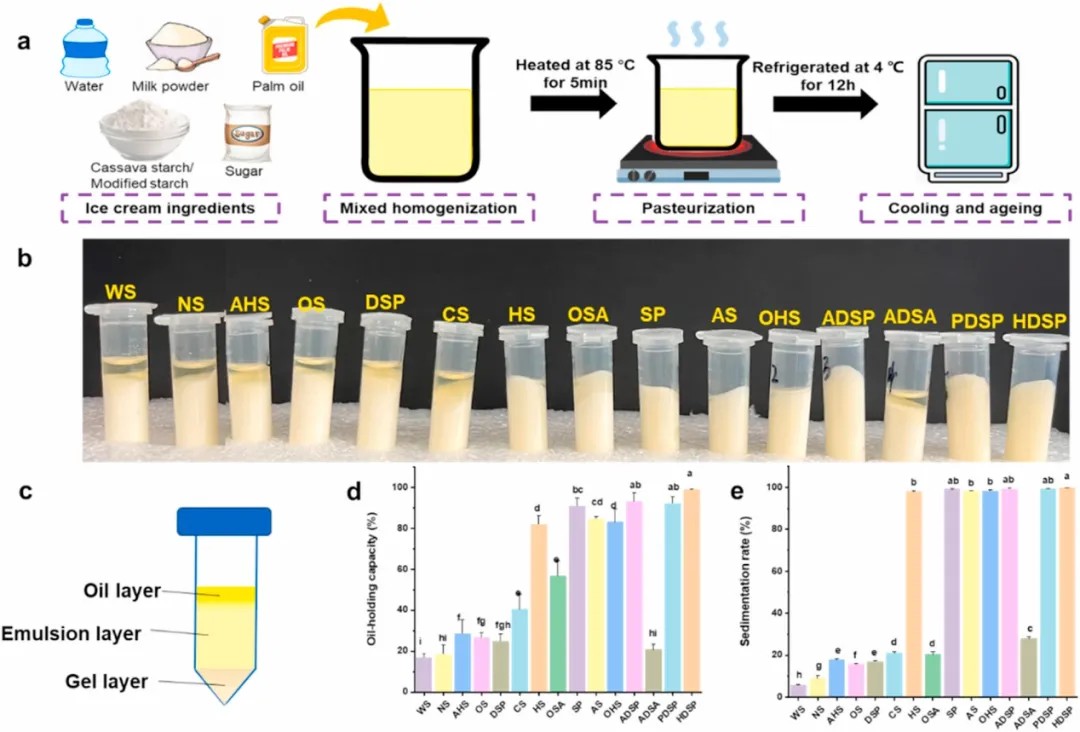

3.3. 冰淇淋油墨的3D打印性能

Fig. 3. Ice cream cuboids after 3D printing with

different modified starches. HS (a), SP (b), AS (c), OHS(d), ADSP (e),

PDSP (f), HDSP (g), 3D printed logo of Zhejiang University (h), 3D

printed turtle(i).

Fig. 4. The size of the printed ice cream with

different modified starches. (a) Line width; (b) Bottom length; (c) Edge

height; (d) Center height; (e) Printing accuracy of the printed

product.

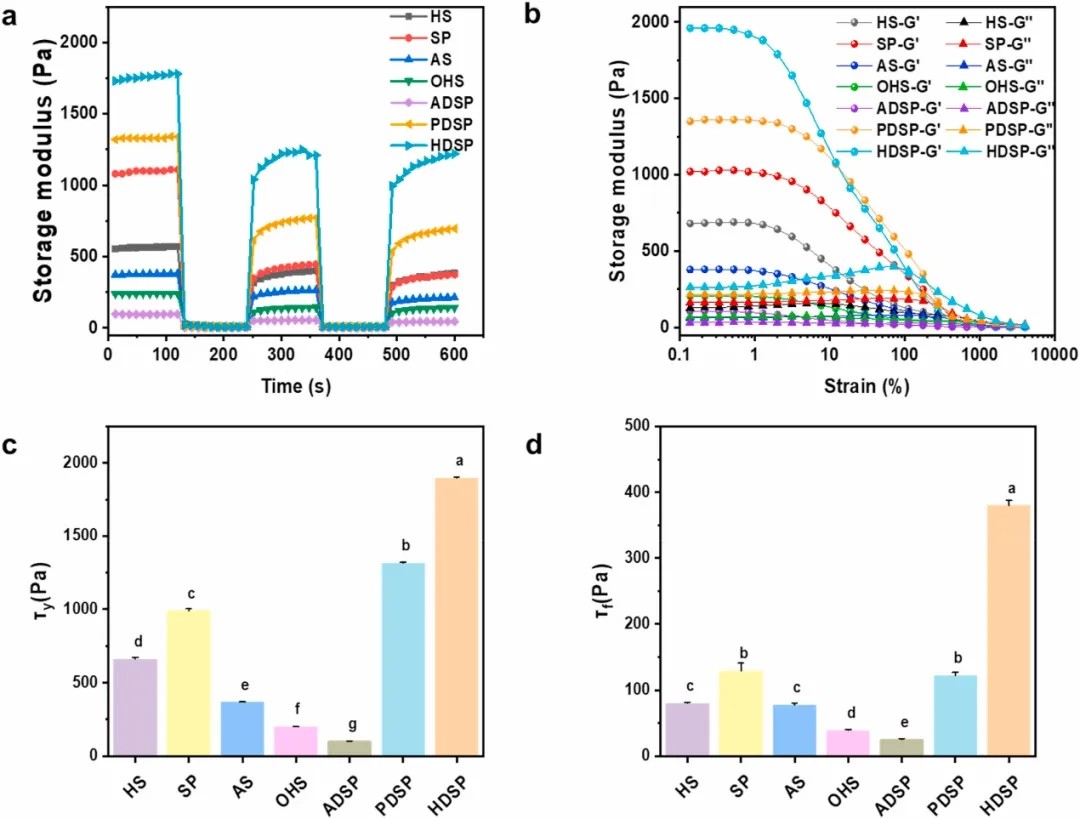

3.4. 冰淇淋油墨的触变性和机械强度

Fig. 5. Ice cream inks prepared with different

modified starches with structural recovery properties (a); mechanical

properties (b); yield stress (c); flow stress (d).

3.5. 冰淇淋油墨的水分分布

Fig. 6. Water distribution of ice cream ink (a); Water distribution content(b).

3.6. 冰淇淋油墨的纳米聚集体结构

Fig. 7. Kratky plots (a), Ornstein-Zernike fit

curves (b) and correlation length (c) of ice cream inks prepared with

different modified starches.

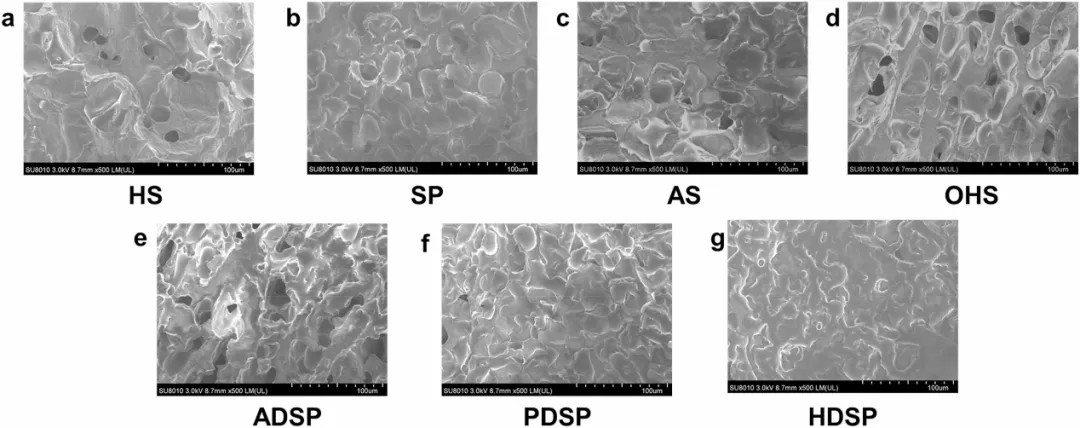

3.7. 印刷品内部结构形貌

Fig. 8. SEM images of 3D printed of ice cream prepared with different modified starches.

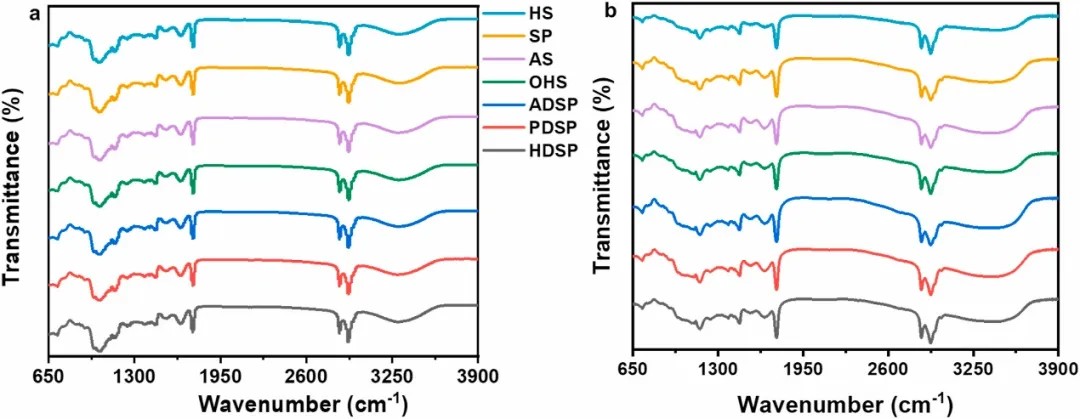

3.8. 冰淇淋油墨的 FTIR 分析

Fig. 9. FTIR spectra of ice cream inks prepared with

different modified starches after physical mixing (a) and

pasteurization (b).

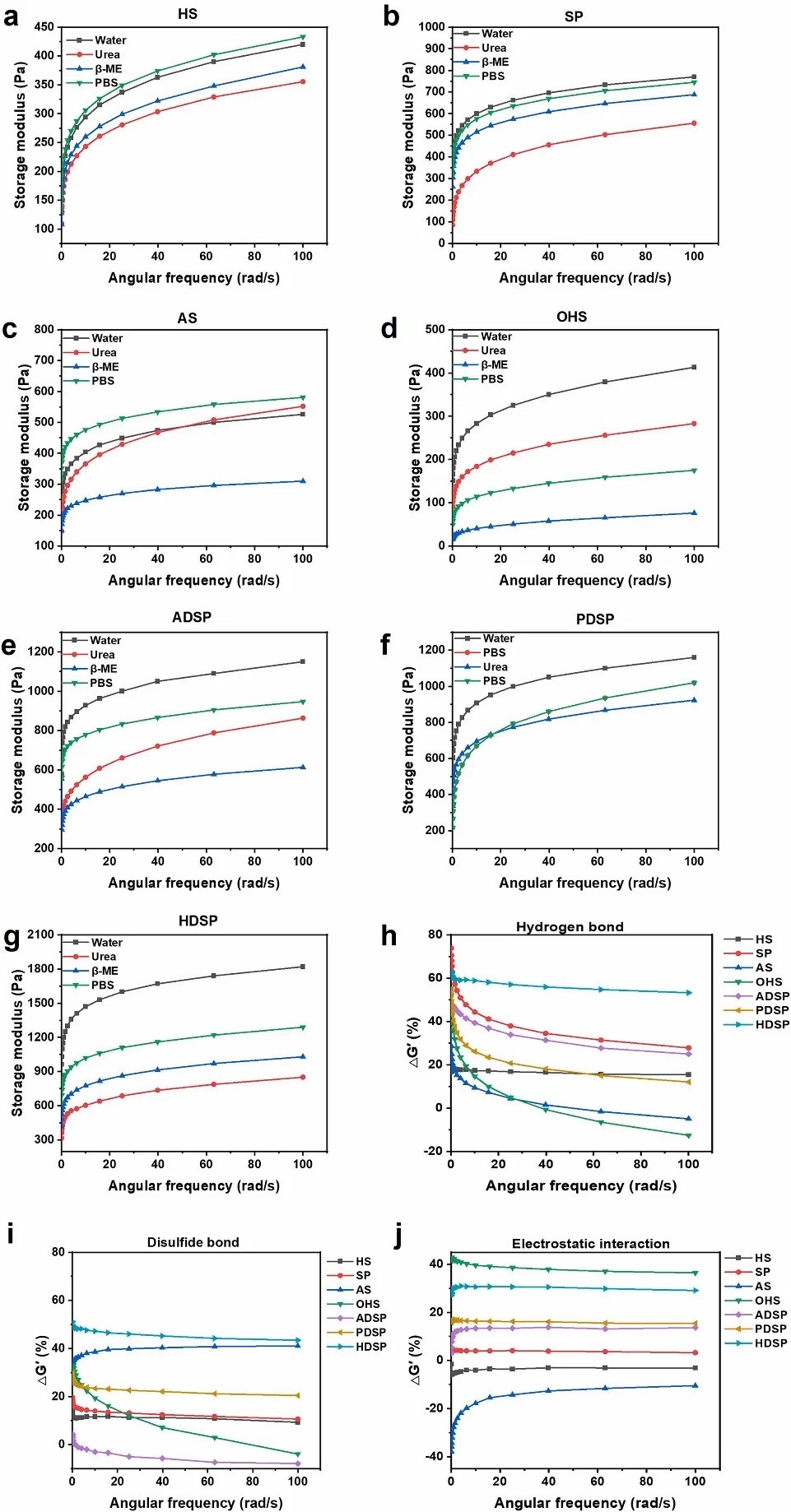

3.9. 冰淇淋油墨中的分子相互作用力

Fig. 10. Intermolecular forces (hydrogen bonding,

disulfide bonding) in ice cream inks prepared with different modified

starches. HS (a), SP (b), AS (c), OHS(d), ADSP (e), PDSP (f), HDSP (g),

hydrogen bonding (h), disulfide bond(i), electrostatic interaction.

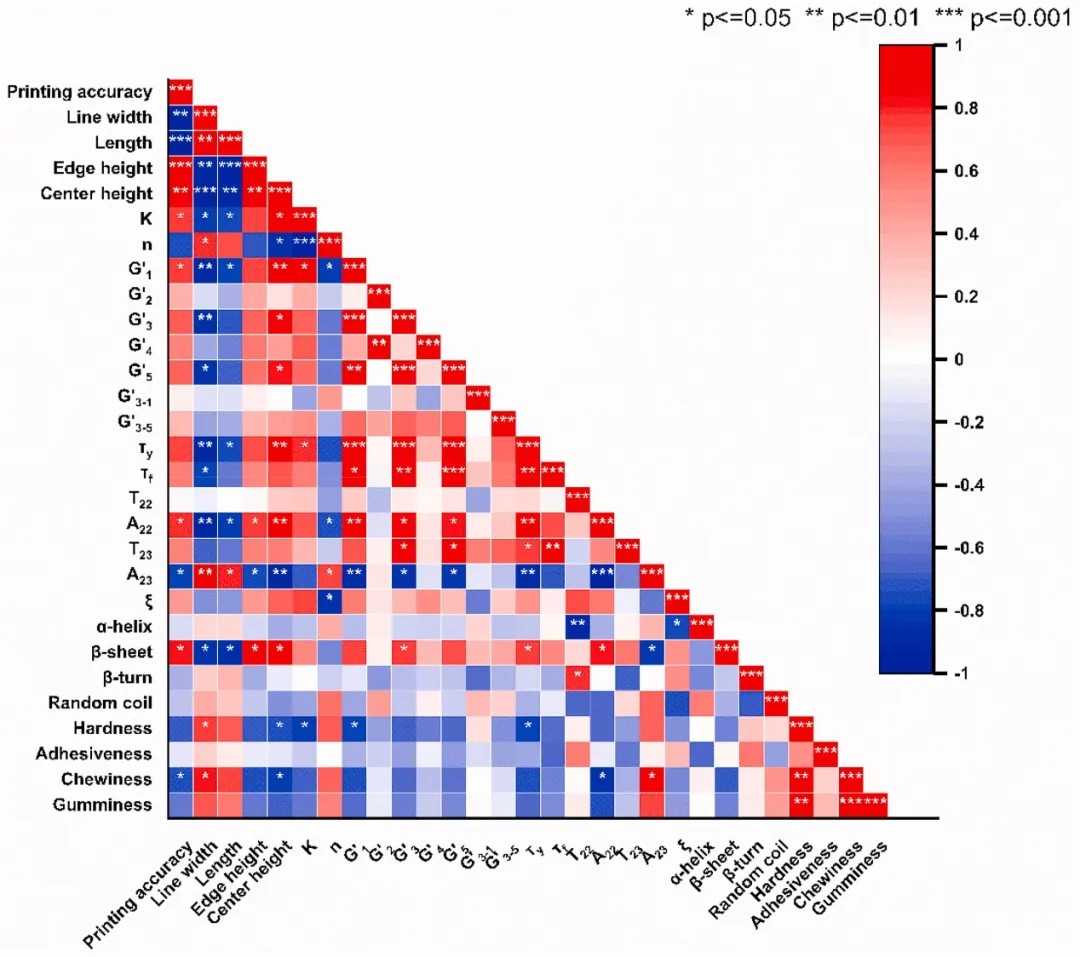

3.11. 各种变性淀粉制备的结构、油墨性能与3D打印产品之间的关系

Fig. 11. The relationship between the structure and properties of ice cream ink prepared with various modified starches.

原文链接:

https://doi.org/10.1016/j.foodhyd.2024.110038

(责任编辑:admin)

最新内容

热点内容

中南大学:增材制备可生物

中南大学:增材制备可生物 2024年二季度,中国3D打印

2024年二季度,中国3D打印 《Bioactive Materials》

《Bioactive Materials》 增材制造中机器学习研究综

增材制造中机器学习研究综 高性能水凝胶的3D生物打印

高性能水凝胶的3D生物打印 研究人员开创使用X射线和

研究人员开创使用X射线和 选区激光熔化增材

选区激光熔化增材 大型聚合物3D打印

大型聚合物3D打印 6K Additive最新

6K Additive最新 如何打造增材制造

如何打造增材制造 从实验室走向生产

从实验室走向生产 3D打印在口腔修复

3D打印在口腔修复